What is Robotics Automation and How Does It Work?

In recent years, the field of robotics automation has experienced significant growth. According to a report by McKinsey, automation could raise global productivity by 0.8 to 1.4 percent annually. Many industries have embraced robotics automation to streamline operations. Manufacturing, logistics, and healthcare are leading the way. By 2026, the global market for robotics is expected to exceed $200 billion.

Robotics automation can enhance efficiency and reduce human error. For instance, robots can perform tasks at remarkable speeds. Yet, challenges remain. Many workers fear job displacement. The social implications of automation must be addressed to avoid backlash. Businesses should consider transitioning carefully.

Moreover, integrating robotics automation requires investment and skilled personnel. Training programs can help bridge the skills gap. Yet, some organizations struggle to keep pace with technology. As the industry evolves, staying updated is crucial. The balance between innovation and workforce stability will define the future of robotics automation.

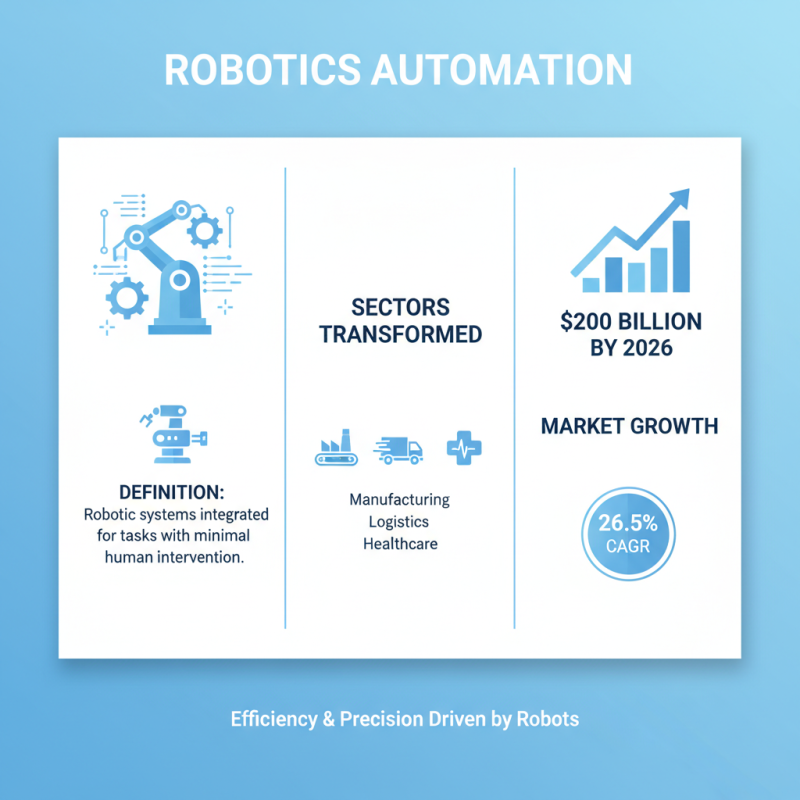

Definition and Overview of Robotics Automation

Robotics automation refers to the integration of robotic systems to perform tasks with minimal human intervention. This technology has transformed industries such as manufacturing, logistics, and healthcare. According to a recent market research report, the robotics automation market is expected to reach $200 billion by 2026, reflecting a compound annual growth rate (CAGR) of 26.5%. This shows the growing reliance on robots and automation for efficiency and precision.

Robotics automation can streamline processes and reduce errors. Robots can work around the clock and handle repetitive tasks with high accuracy. However, the implementation of such systems may face challenges. Employees often need retraining, and there can be resistance to change. Organizations must weigh the benefits against potential disruptions.

**Tips:** Evaluate your team's readiness for automation. Have open discussions about concerns. Encourage feedback and engagement to ease the transition. Training programs should be tailored to ensure successful integration. Look for balance; technology must complement human workers, not replace them.

Key Components of Robotics Automation Systems

Robotics automation integrates various key components to function effectively. At its core, sensors play a crucial role. Sensors detect environmental changes and provide data. They help robots understand their surroundings. Common types include cameras, lidar, and tactile sensors. Each type offers unique benefits. Without these, robots lack perception.

Another essential component is the actuator. Actuators convert electrical signals into movement. They drive the mechanical parts of the robot. This can be motors or hydraulic systems. Precision is vital here. If the actuator fails, the robot's function is compromised. Robotics design often demands a balance between power and control.

Tips: Always consider the task at hand. Simpler systems can perform specific jobs efficiently. Over-complex designs may lead to failures. Testing under different conditions is vital for reliable automation. Reflection on design choices can lead to improvements. Don't shy away from flaws; they guide development.

Robotics Automation System Components

How Robotics Automation Works: Processes and Technologies

Robotics automation is revolutionizing industries by using technology to streamline processes. At its core, robotics automation involves machines performing tasks traditionally done by humans. This technology integrates various components like sensors, software, and mechanical systems. Robots can work tirelessly, enhancing efficiency and precision in production lines. They perform repetitive tasks, freeing human workers for more complex roles.

The processes involved in robotics automation are varied. First, robots gather data through sensors, which helps them understand their environment. They then analyze this data using sophisticated algorithms. After processing input, robots execute tasks based on pre-defined parameters. This ability allows them to adapt to changing conditions. However, automation can lead to employment concerns. Workers may feel threatened by the rapid adoption of robots. There’s often a need to rethink workforce dynamics and retrain staff.

Technologies like artificial intelligence enhance robotics automation further. AI allows robots to learn from experiences, improving their performance over time. Yet, this creates dilemmas. How much autonomy should robots have? It challenges traditional notions of control and oversight. The balance between human oversight and robotic independence is still being explored. These are just some of the complexities within the realm of robotics automation.

Applications of Robotics Automation in Various Industries

Robotics automation is transforming industries globally. In manufacturing, robots enhance productivity. According to a recent report, over 80% of companies increase efficiency with automation. Tasks such as assembly and quality control are streamlined. This leads to significant reductions in production time.

The healthcare industry also benefits greatly. Robots assist in surgeries and manage supply chains. A study indicates that robotic surgeries can reduce recovery time by up to 30%. However, there are challenges. Integrating robotics requires substantial training for staff. Not all hospitals are ready for this shift.

In logistics, automation improves delivery times. Autonomous vehicles navigate warehouses efficiently. Data shows that companies adopting robotic systems can cut costs by 25%. Yet, implementing these systems isn't always smooth. There are technical failures and the need for constant updates. The reliance on automated systems raises questions about future employment.

What is Robotics Automation and How Does It Work? - Applications of Robotics Automation in Various Industries

| Industry | Application | Benefits | Challenges |

|---|---|---|---|

| Manufacturing | Automated assembly lines | Increased production speed and reduced labor costs | High initial investment and maintenance costs |

| Retail | Robotic process automation for inventory management | Streamlined operations and improved inventory accuracy | Integration with existing systems can be complex |

| Healthcare | Surgical robots and automated medication dispensing | Increased precision and reduced human error | High training requirements for staff |

| Transportation | Autonomous vehicles and drones for delivery | Reduced delivery times and increased efficiency | Regulatory hurdles and public acceptance issues |

| Agriculture | Automated planting and harvesting solutions | Higher crop yields and reduced labor needs | Dependence on technology and potential for malfunction |

Future Trends and Developments in Robotics Automation

The future of robotics automation is vibrant and full of potential. Automation technology is advancing rapidly, impacting various sectors. One clear trend is the integration of artificial intelligence with robotics. This combination enhances decision-making processes and increases efficiency. However, challenges remain. Ethical concerns about job displacement arise as machines take over tasks traditionally performed by humans.

Additionally, the development of collaborative robots, or cobots, is on the rise. These robots work alongside humans to improve productivity. They are designed to interact safely in shared environments. As industries embrace this model, training becomes essential. Workers must adapt to new tools and practices. This transition is not always smooth, leading to resistance and hesitation.

Moreover, the evolution of robots with improved sensory capabilities is exciting. They can perceive their surroundings more effectively. This opens new possibilities in sectors like healthcare and logistics. Yet, the complexity of implementing such technology may present hurdles. Not all organizations are ready to adapt. The balance between embracing innovation and managing change is critical as we move forward.

Related Posts

-

10 Best Robotics Automation Trends Transforming Industries in 2023

-

Unlocking the Future of Work with Robotics and Automation Trends and Innovations in 2023

-

What is Robotics and Automation Driving the Future of Industry with 25 Percent Growth by 2025

-

Unlocking Efficiency: How Collaborative Robots are Transforming Modern Industries

-

How to Effectively Implement Collaborative Robots in Manufacturing Processes

-

2026 Best Robotic Systems Innovations to Transform Industries?